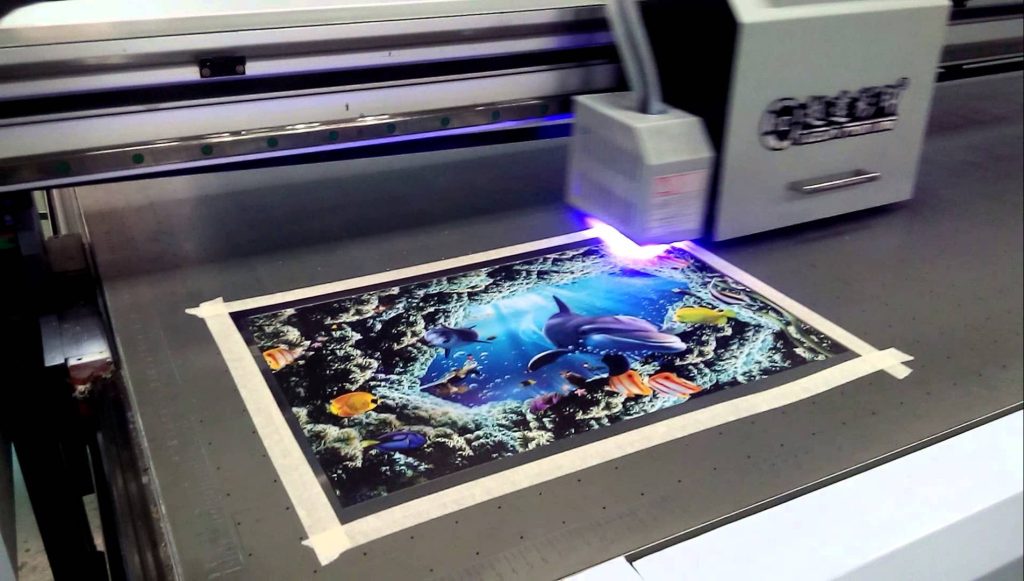

A Comprehensive Walkthrough of the UV Printing Process

In the realm of modern printing technology, UV printing has rapidly risen to prominence due to its versatility, efficiency, and remarkable capabilities. To truly appreciate its impact and potential, let’s delve deeper into the intricacies and various aspects of UV printing.

The Photoinitiation Magic

At the heart of the UV printing process lies the remarkable concept of photoinitiation. UV-curable inks contain special compounds called photoinitiators, which remain in a liquid state until they are exposed to ultraviolet (UV) light. When these photoinitiators are subjected to UV light, they undergo a rapid chemical reaction, triggering the polymerization of the ink. This transformation from a liquid to a solid state occurs virtually instantaneously, thanks to the high-intensity UV light emitted by the UV lamp.

This unique property of UV inks provides several advantages:

- Instant Curing: The instant drying and curing of UV ink prevent it from smudging or smearing, even on non-absorbent surfaces like glass or metal. This immediate curing also allows for double-sided printing without the risk of ink transfer.

- Precision and Detail: The rapid curing process ensures that the printed dots or droplets of ink remain in their intended positions, resulting in sharp and highly detailed prints. Fine text, intricate graphics, and complex patterns can be reproduced with exceptional accuracy.

- Reduced Ink Absorption: Unlike traditional solvent-based inks that are absorbed into the substrate, UV ink stays on the surface. This limited absorption results in more vibrant colors and improved print clarity.

- Environmentally Friendly: UV printing produces minimal volatile organic compounds (VOCs) and reduces the emission of harmful fumes, making it an eco-friendly printing option.

Print Head Technology

The print head is a critical component of any printing technology, and UV printing is no exception. Advanced print heads are essential for precise ink deposition and impeccable print quality. Two common types of print heads used in UV printing are piezoelectric and thermal inkjet.

- Piezoelectric Print Heads: These print heads use piezoelectric crystals to create pressure waves that expel ink droplets onto the substrate. They offer precise control over droplet size and placement, resulting in high-resolution prints.

- Thermal Inkjet Print Heads: Thermal inkjet print heads use heat to vaporize ink and create pressure, propelling ink droplets onto the substrate. They are known for their speed and reliability.

The choice of print head technology depends on factors such as the specific UV printer model, intended application, and desired print quality. Both technologies have their strengths, and UV printer manufacturers carefully select the appropriate print head technology to meet the demands of their target market.

Substrate Compatibility

One of the most impressive attributes of UV printing is its versatility when it comes to substrates. UV ink adheres exceptionally well to a wide range of materials, making it suitable for numerous applications:

- Paper and Cardboard: UV printing can produce vibrant and sharp images on standard paper and cardboard, making it suitable for brochures, business cards, and packaging.

- Plastics: UV printing excels on plastic substrates, including PVC, acrylic, and polycarbonate. This makes it ideal for producing durable signage, promotional items, and point-of-purchase displays.

- Glass and Metal: UV printing on glass and metal surfaces is increasingly popular for applications like custom glassware, metal signage, and decorative glass panels.

- Wood and Fabric: With the right pre-treatment, UV printing can be applied to wood and fabric materials, expanding its use to furniture, textiles, and more.

- Ceramics and Tiles: UV printing has found a niche in the ceramics industry, allowing for intricate designs on tiles, dishes, and decorative ceramic pieces.

- Direct-to-Substrate Printing: This cutting-edge application of UV printing eliminates the need for labels or adhesive prints. UV printing can directly print onto materials like metal, plastic, glass, and wood, opening up new possibilities in product customization and design.

The Evolution of UV Inks

As UV printing technology continues to advance, so do the formulations of UV inks. In response to the growing demand for more environmentally friendly printing options, manufacturers are developing UV inks that are eco-conscious. These inks contain fewer volatile organic compounds (VOCs) and are formulated with sustainability in mind.

Additionally, UV inks are evolving to offer enhanced adhesion properties, especially for challenging substrates like plastics and glass. Improved ink formulations are enabling UV printing to expand its footprint across various industries, from automotive and electronics to architectural and interior design.

Special Effects and UV Printing

Beyond its exceptional color reproduction and clarity, UV printing is also capable of producing striking special effects:

- Embossing: UV printing can create raised or embossed textures on the printed surface, adding depth and tactile qualities to printed materials.

- Spot Varnish: By selectively applying varnish to specific areas of a print, UV printing can create glossy, eye-catching highlights that draw attention to key elements.

- Texture Printing: UV printers equipped with texture printing capabilities can simulate textures like leather, wood grain, or even fabric, enhancing the realism and appeal of printed materials.

- White Ink Printing: UV printers often have the option to print white ink. This allows for printing on dark or transparent substrates, resulting in vibrant and opaque prints.

UV Printing and Sustainable Practices

In an era where sustainability is a top priority for many businesses, UV printing has emerged as a responsible choice. Its eco-friendly characteristics, such as reduced VOC emissions and minimal energy consumption due to instant curing, align with environmental goals. Additionally, the longevity and durability of UV-cured prints reduce the need for frequent reprints, further minimizing environmental impact.

The Future of UV Printing

The future of UV printing holds great promise as technology continues to advance:

- Enhanced Inks: Research is ongoing to develop UV inks that are even more environmentally friendly and offer additional capabilities, such as increased flexibility for printing on curved surfaces.

- Automation and Robotics: Automation is becoming more prevalent in UV printing, reducing the need for manual intervention and enhancing efficiency. Robotics are increasingly integrated into UV printing workflows, further streamlining production.

- Customization and Personalization: As consumer preferences continue to shift toward personalized products and packaging, UV printing will play a pivotal role in meeting these demands. Its ability to deliver high-quality, customized prints in real-time makes it an ideal choice for businesses looking to offer personalized products.

- 3D Printing Integration: The integration of UV printing into 3D printing processes is an exciting development. This fusion allows for the creation of intricate, multi-material 3D objects with remarkable precision.

- Medical and Electronics Applications: UV printing is finding applications in the medical and electronics industries, including the production of medical devices, circuit boards, and electronics components.

The UV printing process is a transformative technology that has revolutionized the printing industry. Its ability to instantly cure inks, exceptional print quality, and substrate versatility have made it a preferred choice for various applications across diverse industries. As technology continues to advance and environmental considerations take center stage, UV printing is poised to play an increasingly vital role in the future of printing, offering endless possibilities for innovation and creative expression. Understanding the nuances and capabilities of UV printing empowers businesses and designers to harness its potential and explore new frontiers in print technology.

Now, let’s take an even more comprehensive journey into the fascinating world of UV printing.

Unraveling the UV Printing Process

To fully grasp the significance and intricacies of UV printing, it’s essential to explore each facet in more detail. Let’s embark on a comprehensive journey into the UV printing process, uncovering its principles, advantages, applications, and the promising future it holds.

Photoinitiation: The Magic of Instant Curing

At the core of UV printing lies the fascinating concept of photoinitiation. UV-curable inks contain photoinitiators that remain in a liquid state until exposed to ultraviolet (UV) light. This exposure triggers a rapid chemical reaction, leading to the polymerization of the ink, transforming it from liquid to solid within moments. This instantaneous curing is made possible by the high-intensity UV light emitted by the UV lamp.

This unique property of UV inks offers several remarkable advantages:

- Immediate Curing: UV ink dries and cures instantly upon exposure to UV light, preventing smudging or smearing. This characteristic allows for double-sided printing without the risk of ink transfer.

- Precision and Detail: The rapid curing process ensures that printed dots or droplets of ink remain precisely where they are intended, resulting in sharp, highly detailed prints. Fine text, intricate graphics, and complex patterns can be reproduced with exceptional accuracy.

- Minimal Ink Absorption: In contrast to traditional solvent-based inks, which are absorbed into substrates, UV ink remains on the surface. This limited absorption results in more vibrant colors and improved print clarity.

- Eco-Friendliness: UV printing produces minimal volatile organic compounds (VOCs) and reduces the emission of harmful fumes, making it an environmentally responsible choice.

The Crucial Role of Print Head Technology

The print head is a pivotal component of any printing technology, and UV printing is no exception. Advanced print heads are essential for precise ink deposition and impeccable print quality. Two prevalent types of print heads used in UV printing are piezoelectric and thermal inkjet.

- Piezoelectric Print Heads: These print heads employ piezoelectric crystals to create pressure waves that expel ink droplets onto the substrate. They offer precise control over droplet size and placement, resulting in high-resolution prints.

- Thermal Inkjet Print Heads: Thermal inkjet print heads utilize heat to vaporize ink, generating pressure that propels ink droplets onto the substrate. They are renowned for their speed and reliability.

The selection of print head technology depends on various factors, including the specific UV printer model, the intended application, and the desired print quality. Both piezoelectric and thermal inkjet technologies have their unique strengths, and UV printer manufacturers carefully choose the appropriate technology to cater to the demands of their target market.

The Versatility of Substrate Compatibility

One of the standout features of UV printing is its extraordinary versatility concerning substrates. UV ink exhibits exceptional adhesion to a wide array of materials, making it suitable for numerous applications:

- Paper and Cardboard: UV printing can produce vibrant and sharp images on standard paper and cardboard, making it ideal for applications such as brochures, business cards, and packaging.

- Plastics: UV printing excels on plastic substrates, including PVC, acrylic, and polycarbonate. This versatility makes it an ideal choice for producing durable signage, promotional items, and point-of-purchase displays.

- Glass and Metal: UV printing on glass and metal surfaces is increasingly popular for applications like custom glassware, metal signage, and decorative glass panels.

- Wood and Fabric: With the appropriate pre-treatment, UV printing can be applied to wood and fabric materials, expanding its use to furniture, textiles, and more.

- Ceramics and Tiles: UV printing has found a niche in the ceramics industry, allowing for intricate designs on tiles, dishes, and decorative ceramic pieces.

- Direct-to-Substrate Printing: A cutting-edge application of UV printing eliminates the need for labels or adhesive prints. UV printing can directly print onto materials like metal, plastic, glass, and wood, opening up new possibilities in product customization and design.

The Evolution of UV Inks: Toward Sustainability

As UV printing technology continues to advance, so do the formulations of UV inks. In response to the growing demand for more environmentally friendly printing options, manufacturers are developing UV inks with eco-conscious formulations. These inks contain fewer volatile organic compounds (VOCs) and are crafted with sustainability in mind.

Additionally, UV inks are evolving to offer enhanced adhesion properties, particularly for challenging substrates like plastics and glass. These improved ink formulations are enabling UV printing to expand its presence across various industries, from automotive and electronics to architectural and interior design.

Exploring Special Effects in UV Printing

Beyond its exceptional color reproduction and clarity, UV printing is also renowned for its ability to produce striking special effects:

- Embossing: UV printing can create raised or embossed textures on the printed surface, adding depth and tactile qualities to printed materials.

- Spot Varnish: By selectively applying varnish to specific areas of a print, UV printing can create glossy, eye-catching highlights that draw attention to key elements.

- Texture Printing: UV printers equipped with texture printing capabilities can simulate textures like leather, wood grain, or even fabric, enhancing the realism and appeal of printed materials.

- White Ink Printing: UV printers often have the option to print white ink. This allows for printing on dark or transparent substrates, resulting in vibrant and opaque prints.

UV Printing and Sustainable Practices

In an era where sustainability is a top priority for many businesses, UV printing has emerged as a responsible choice. Its eco-friendly characteristics, such as reduced VOC emissions and minimal energy consumption due to instant curing, align with environmental goals. Additionally, the longevity and durability of UV-cured prints reduce the need for frequent reprints, further minimizing environmental impact.

The Future of UV Printing

The future of UV printing holds great promise as technology continues to advance:

- Enhanced Inks: Ongoing research aims to develop UV inks that are even more environmentally friendly and offer additional capabilities, such as increased flexibility for printing on curved surfaces.

- Automation and Robotics: Automation is becoming more prevalent in UV printing, reducing the need for manual intervention and enhancing efficiency. Robotics are increasingly integrated into UV printing workflows, further streamlining production.

- Customization and Personalization: As consumer preferences continue to shift toward personalized products and packaging, UV printing will play a pivotal role in meeting these demands. Its ability to deliver high-quality, customized prints in real-time makes it an ideal choice for businesses looking to offer personalized products.

- **3

D Printing Integration:** The integration of UV printing into 3D printing processes is an exciting development. This fusion allows for the creation of intricate, multi-material 3D objects with remarkable precision.

- Medical and Electronics Applications: UV printing is finding applications in the medical and electronics industries, including the production of medical devices, circuit boards, and electronics components.

The UV printing process represents a convergence of cutting-edge technology and creative possibilities. Its ability to consistently produce high-quality prints on a multitude of substrates, combined with its environmental benefits, has made it a preferred choice in various industries. As technology continues to advance and adapt to the changing landscape of printing and manufacturing, UV printing is poised to play an increasingly pivotal role. Whether it’s in the realm of high-quality signage, personalized promotional products, or even intricate 3D printing, UV printing is poised to leave an indelible mark on the future of the printing industry, promising exciting possibilities and endless potential for innovation. Understanding the intricate principles and advantages of UV printing empowers businesses, designers, and printing professionals to explore innovative avenues and stay at the forefront of modern printing technology.

Now that we’ve taken an even more comprehensive journey through the UV printing process, you have a deeper understanding of its capabilities and potential, setting the stage for the next wave of innovations and possibilities in the world of printing.